How to Select the Right Flexible Heating Element

If you’ve ever used a heated blanket or warmed up your car seat, you’ve experienced the benefits of a flexible heating element. However, consumer applications are only a tiny part of the market. Flexible heating elements are used for temperature regulation in vending machines, manufacturing equipment, and medical devices, among many other applications.

What is a flexible heating element, and what are the benefits?

A flexible heating element can mold into various spaces. Some are screen printed onto a flexible material, while others are made from silicone rubber or a thin polymer. The result is a versatile part that can be sized to fit a manufacturer’s needs.

And customizability is only one benefit of flexible heating elements. They can keep out-gassing at a minimum while providing quick, even heat distribution where your product needs it. Flexible heating elements are moisture-resistant and less likely to mold. They can be attached to surfaces using pressure-sensitive adhesives or vulcanization for a thin, moldable solution.

Hi-Heat’s Flexible Heating Elements

Hi-Heat helps original equipment manufacturers and businesses determine how to select the correct flexible heating elements for their products. Our elements are available in various materials, each with unique benefits.

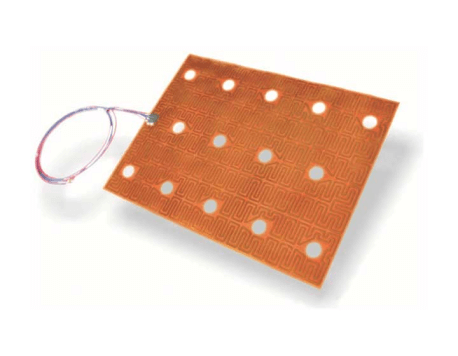

Silicone Rubber Heater

A custom silicone rubber heater brings benefits for applications that need a continuous operating temperature of 200° Celsius or 392° Fahrenheit. Industrial silicone rubber heaters have a dielectric strength of 400 to 600 volts per mil thickness.

Silicone rubber heaters are the go-to option when fast heat transfer rates are essential. This lightweight, thin material can squeeze into tight spaces.

Hi-Heat’s silicone rubber heaters can be custom-built to your exact specifications, and they can also be mounted to various surfaces.

Applications that benefit from silicone rubber heating elements:

- Medical equipment, like respiratory therapy units and blood analyzers

- Wafer production equipment, which is used in integrated circuit manufacturing

- Vending machines and food-warming equipment

- Satellites and technology equipment, including laser printers

Types of Silicone Rubber Heaters

There are two types of silicone rubber flexible heaters. For superior performance, go with an etched foil silicone rubber heater, which can operate in ambient temperatures ranging from -62° to 260° Celsius or -80° to 500° Fahrenheit. This high-quality, custom heater allows for complex heat distribution, making it perfect for equipment requiring lower wattage per square inch.

The wire-wound silicone rubber heater is a more affordable alternative for most applications. A wire-wound silicone rubber heater mixes nickel-chromium alloy wire with fiberglass twine, designed to evenly heat across its surface. This element is more affordable, and its prototype design process is quicker, making it the best solution for many equipment types.

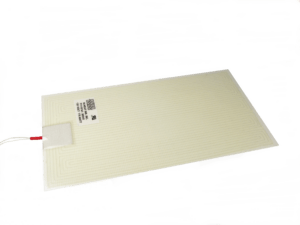

Polyester Heaters

Polyester has become the go-to material across a variety of industries. The best thing about polyester flexible heaters is their versatility. Polyester film heaters can be designed with notches, adhesive backing, and other options to make them the best fit.

One downside of polyester heating elements is its low heat tolerance, which makes it perfect for equipment with low heat output.

Typical applications include:

- Touchscreen panels

- Heated mirrors

- Battery warmers

- Medical equipment

- Restaurant Equipment

- Deicing equipment

- Cosmetic equipment

- Heated aquariums

Types of Polyester Heaters

To help you select the correct flexible heating element, it is essential to know the differences between the two significant types of polyester flexible heating elements. The first is an etched foil polyester heater, which, like etched silicone rubber, is best for more complex applications. Etched foil polyester heaters use lower wattage per square inch but distribute that wattage more evenly, giving you a reliable solution.

A more economical alternative is a wire-wound polyester heater. Wire-wound polyester heaters combine a fine nickel-chromium alloy wire with fiberglass, similar to the design of wire-wound silicone rubber heating elements. These offer faster prototypes at a lower overall cost, making them a better option for businesses that don’t need the premium features built into the etched foil polyester option.

With both types of polyester heaters, you get moisture resistance and versatility. While these aren’t the only moisture-resistant heater options, they provide high-limit protection and the option of built-in notches to make mounting easy. Polyester flexible heating elements have a lower temperature threshold than silicone rubber, with a temperature capacity limit of 105° Celsius and 221° Fahrenheit.

Polyester Heaters

Heat surfaces of any size and shape. Customizations include adhesive backing, notches, control measures, and insulation.Kapton Heaters

If you want to select a flexible heating element with a high heat capacity, Kapton may be your answer! Kapton heaters can withstand temperatures up to 260° Celsius or 500° Fahrenheit. Hi-Heat combines polyimide film with etched foil circuits to produce a thin but highly effective Kapton flexible heating element.

A Kapton heater is made from polyimide film, a lightweight, transparent material known for its heat resistance. Polyimide film is also relied on for its dielectric properties, providing insulation and transmitting electricity without conduction. All of this makes it an ideal candidate for flexible heating.

When you have a custom polyimide heater designed, you’re getting extreme accuracy in the design process. Kapton heating elements can be customized to 0.10 inches. This allows original equipment manufacturers to get a heating element sized to easily squeeze into curved spaces.

One of the best things about a polyimide Kapton heater is its flexibility. Despite its ultra-thin build, a Kapton flexible heating element is powerful and durable, so once placed, you can rely on it to hold up over the months and years. Polyimide material also holds up when exposed to many types of chemicals, furthering its resilience.

In addition to its tolerance to high heat levels, Kapton’s flexible heating elements can also endure chilly temperatures. Kapton heaters can handle temperatures below -160° Celsius or -320° Fahrenheit. Kapton is a better choice for frigid environments than polyester or silicone rubber.

You’ll typically find Kapton heating elements in heavy-duty systems, including:

- Commercial HVAC systems

- Medical equipment like incubators, infection-reducing heated medical tools, and blood-testing devices

- Aircraft and aerospace satellite equipment

- Food Machinery

Hi-Heat can help you select the correct flexible heating element for your application. With our ability to fill small orders frequently and exceptional customer service, we are ready to put the heat anywhere. Whether you require custom design and prototyping, or your needs could be met with one of our stock heaters on our website store, contact us to get your project started today!